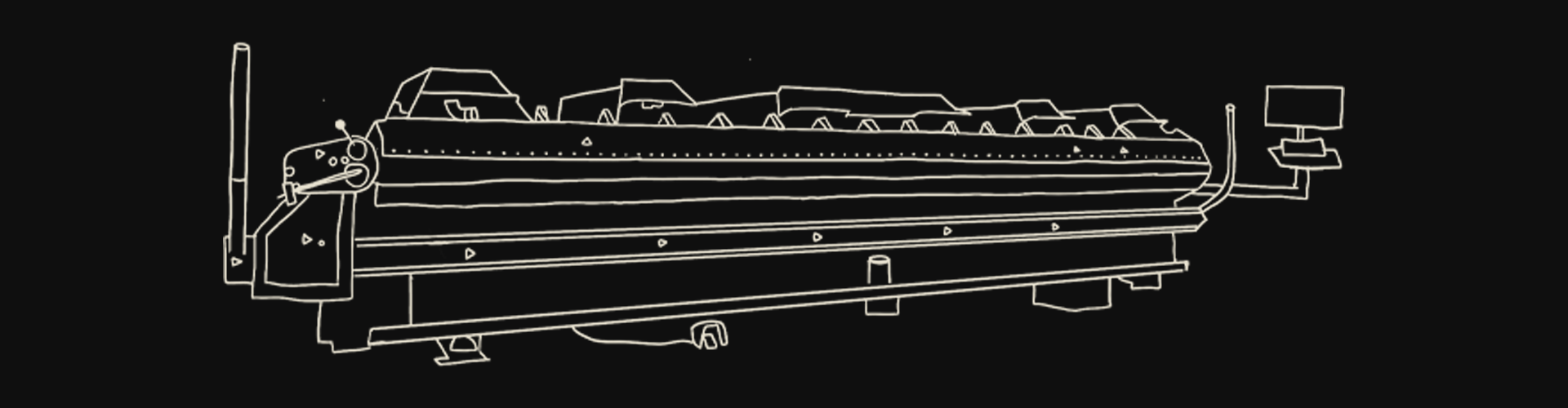

s series

The S Series Single Folder is technically unique compared to other long folders on the market. The geometry of the clamping beam allows the operator to make profiles otherwise impossible.

If the Single Folder isn’t exactly what you’re looking for check out our Double Folder machines.

Feature Spotlight

Torsion Bar

Another improvement is the torsion bar clamping system that gives accurate level closing of the clamping beam even under the load of hemming operations. This feature includes and opening height that is infinitely variable by the touch screen control and allows hemming to maintain an even gap if required.

More features of our

Single Folder

Torsion Bar Clamping

Accurate level closing of the clamping beam even under the load of heavy operations, including the opening height that is infinitely variable by the touch screen control and allows hemming to maintain an even gap if required.

Clamping Bar

Two clamping beam geometry options. V-standard offers a work envelope of 280°. The new V-Curved offers more clearance, allowing for deeper J profiles.

High-Speed Back Gauge

Driven by ball screws with a range of ¼” – 49.2”. The back gauge can manage parts with a taper up to 4”.

Slitter

The slitting assembly slides on dual linear bearing rails mounted directly on the machine chassis, providing a rigid structure. This innovative solution ensures that beams are free from any interference as is typically found on rails mounted on the clamping or bending beam. This slitter cuts up to 3x faster than the industry standard.

Bending Beam

The patented Variobend bending beams are angled back, allowing you to bend profiles that used to be impossible with vertical bending beams.

Hydraulic Components

Featuring SAE hydraulic fittings, hoses, and double filters, the entire hydraulic system is engineered in the USA for maximum performance, efficiency and long term reliability.

Folder

Features

User-Friendly Touch Screen Controls

The 24” touch screen control allows fast and easy input of new profiles as well as a library of standard profiles. A new standard has been set for operator convenience and software possibilities.

Replaceable Hardened Segments

Removable, hardened segments for both the clamping and bending beam make segments easily replaceable. Guaranteed precision for life.

Robust Frame

A folding machine is no better than its foundation, and this is another area where Variobend is superior. An 8” x 12” tubing for the main frame assures ease of setup and consistent accuracy in spite of possible variation in the plant floor.

Contact Sales

- Monday–Friday: 8am–5pm

- 420 Progress Dr, Mattoon, IL 61938

- 877-289-3030

- 217-234-4700

- sales@variobendusa.com